Winguu has years of experience with various paragliding equipment, gliders reserves harnesses and instruments, as seen and worked with for over 25 years.

We closely track the progress in design and technology as it continues to grow by the paragliding gear producing companies.

We evolve with the sport, the latest demand & products released, as to finally reach our #1 important goal that is safety in paragliding followed by performance.

Katerina who runs the service center was specially trained at Sky Paragliders main factory unit in Czech Republic after a primary educational visit at MCC Aviation in Switzerland and the designer Mr Alexander Paux ‘s atelier.

A trustworthy practical methodology, that takes you from A to Z with a natural feel of the fabrics, will serve to reveal the faults and best potentials of the glider and equipment set.

A broad span of information is obtained from the materials, their handling and application properties in paragliding.

The coordinated work and study on the equipment, the assessment of it’s condition and the appropriate proceedings for the repair, adjustment and maintenance – are carried out with utmost care to result in optimal functionality of reliable flying tools for the pilot.

➡ Reference Check / canopy & line reference measurement

A reference check is performed on NEW gliders in order to obtain the authentic original measurements of each line for this particular glider.

This greatly serves for the glider’s future trim adjustment with accuracy, more so for higher-category and smaller deviation (0-5 mm) allowance gliders.

A porosity test on the canopy cloth is also done to observe sensitivities and check for material errors.

➡ Certified Glider Check / visual control and porosity testing

Porosity testing of the glider canopy cloth, of 3 to 5 different points on the canopy, will show the condition of the fabric as to its airworthiness.

Ultimately the ability of the glider to keep its original profile and relevant structural properties the wing was designed to fly by.

The fatigue of the fabric and its coating due to use, environmental exposure, storage and built will eventually affect the inflation, re-inflation and glide behavior of the paraglider.

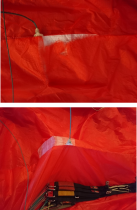

Most tears and holes can be detected and repaired on the top or bottom surface, as among the inner ribs and diagonals of the canopy. These can be effectively sealed, put together with ripstop spinnaker tape or fabric and further sewing.

When necessary pieces can be replaced, like larger material panels with new panels provided from the factory as they will be the exact genuine code match.

Risers undergo measurement too and visual check also for secure stitching and that trim / speed / big ears systems are kept in working order. When necessary components can be replaced, from plastic stops and speed system lines to pulleys and carabiners.

Carabiners or maillons need to be checked as to seal effortlessly and correctly.

Suspension lines, line cascade connections and attachment points are checked for their conformity and endurance, any severe sheet or core deformation and discolouring.

Lines when necessary and after a specific period of times can easily be replaced.

➡ Certified Glider Trim / line length laser-measurement and adjustment

The paraglider lines simply change proportions through time, naturally and according to use.

This leads to changes in the behavior, control and ultimately the safety of the glider.

The glider is brought back to trim balance or tuned in accordance to the manufacturer’s official line-length measurements chart and given allowances.

Measuring the length of each paraglider line by laser is the effective way to view the glider symmetry, right to left riser differences and irregular lengths.

Finally adjusting length is done either with specific loops or repositioning the stitching on the line.

What are the common symptoms of a paraglider out of trim?

- Problems at inflating the glider on take off

- Problematic re-inflation and recovery after collapses

- Difficulty in steering, tendency to fly toward either side

- The glider may become slower or more sensitive to collapses and stalling

When should I check my paraglider?

Paraglider checks should follow both the Use & natural Fatigue of the materials from the environmental elements commonly separated by seasons.

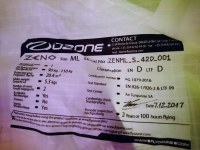

The manufacture companies instruct intervals of 2 years or 100 flying hours as the amount of hours on a glider before it needs to be checked.

This instruction can be found in the glider manual or often written on the glider label.

The paraglider becomes safer and the pilot feels difference in flight and performance.

Read more information about materials used in paraglider manufacture

in the relevant article Material Application Properties in Paragliding

➡ Harness Check / material and compatibility

It is important as a pilot to know how to fully operate your flying tools including your harness.

There is a given geometry by design and it should compliment your glider and your flying style.

For cocoon harnesses as much as pod harnesses there are several adjustments that should be utilized. Not only so that pilots fully benefit from but also to prevent from the harness functioning against them.

Harnesses are mostly made with strong durable materials and the technology on design has evolved greatly.

There are signs that show the deterioration of the materials if you know where to look. It is further important to accommodate the necessity of precaution since these materials would fail abruptly under strain.

➡ Reserve Rescue Parachute Maintenance / material check, re-pack and installation

In any matter concerning reserve rescue parachutes it is best practise to take directions and data provided by the manufacturers, be it any type such as square-round, square, (rogallo) heart shaped or round.

All reserve parachutes have a specified unique serial number, production date and expiration period. They require to be opened, checked, aired, re-packed and re-fitted in a controlled dry environment frequently by following the manufacturer instructions to the letter.

In numbers…

* The life span of an average paragliding reserve parachute is 10 years.

Extension of 5 years may be given after qualifying to a porosity test and lines complete renewal.

* Obligatory to guarantee its function is a precaution check and unpack/repack of the reserve the very least every 2 years.

* Usage allowance is also described in a total of 25 re-packs or 5 SIV deployments in respect to the parachute being in water.

Overall the endurance of the reserve parachute materials is high however caution to its maintenance, pack fitting and harness mounting is very important to make sure it will open and fast.

Continue reading more about Reserve Rescue Parachutes in Paragliding

in the article Reserves useful FAQ knowledge for Paragliding Pilots

➡ Glider LOGOS & PATTERNS

We can easily decorate your glider with your company or sponsor logo moreover fun flying designs.

Let us know what you want, your idea or select from available impressive designs, and we can prepare the pattern as more make a perfect fit to your gliders.

Depending on the glider you wish to stamp we provide the markings that are carefully stuck on the surface of the glider and will last for you the longest of time!